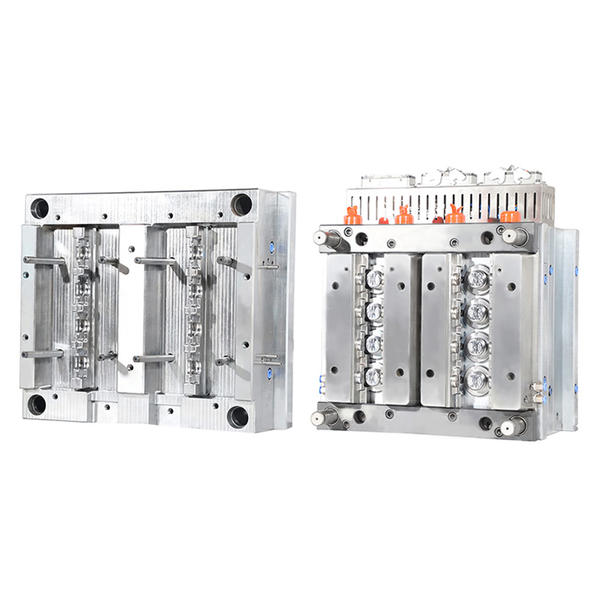

Jar mould

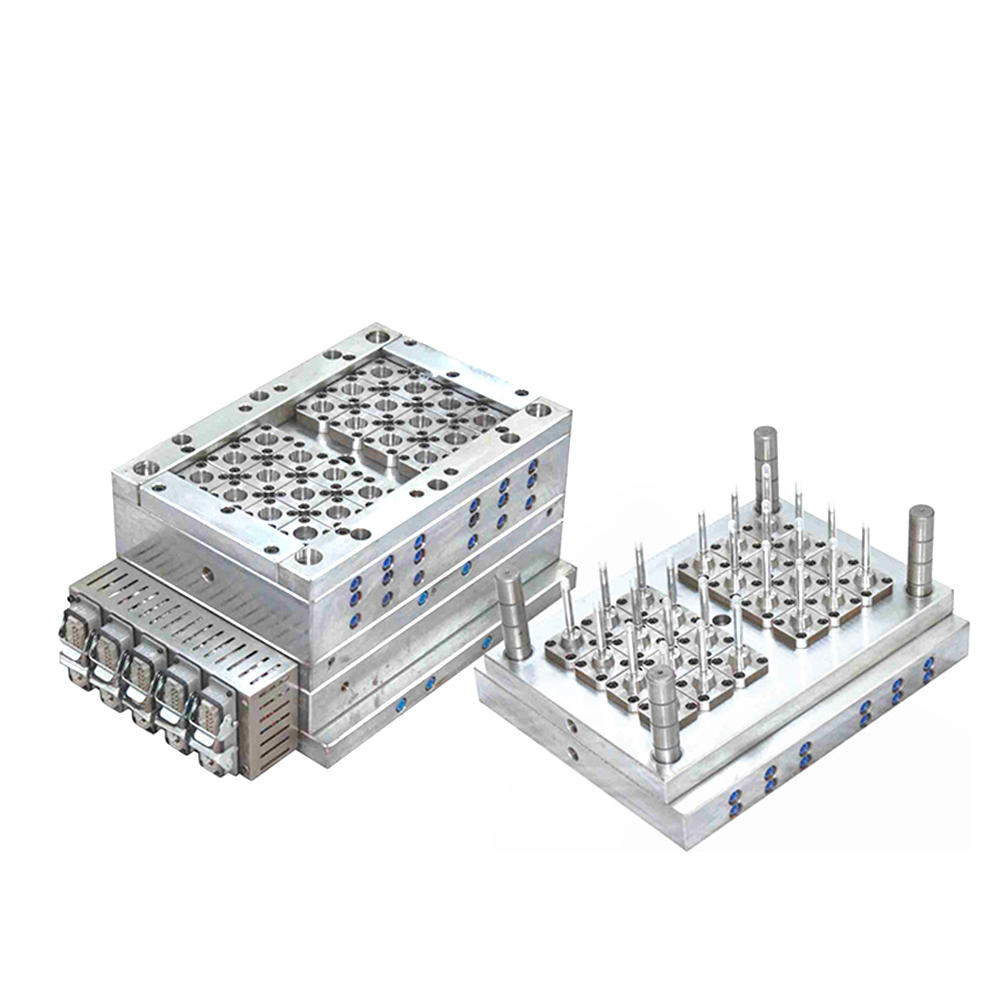

Neck size: 45mm, 53mm, 63mm, 70mm, 90mm, 110mm, 120mm.

-

Products Parameter

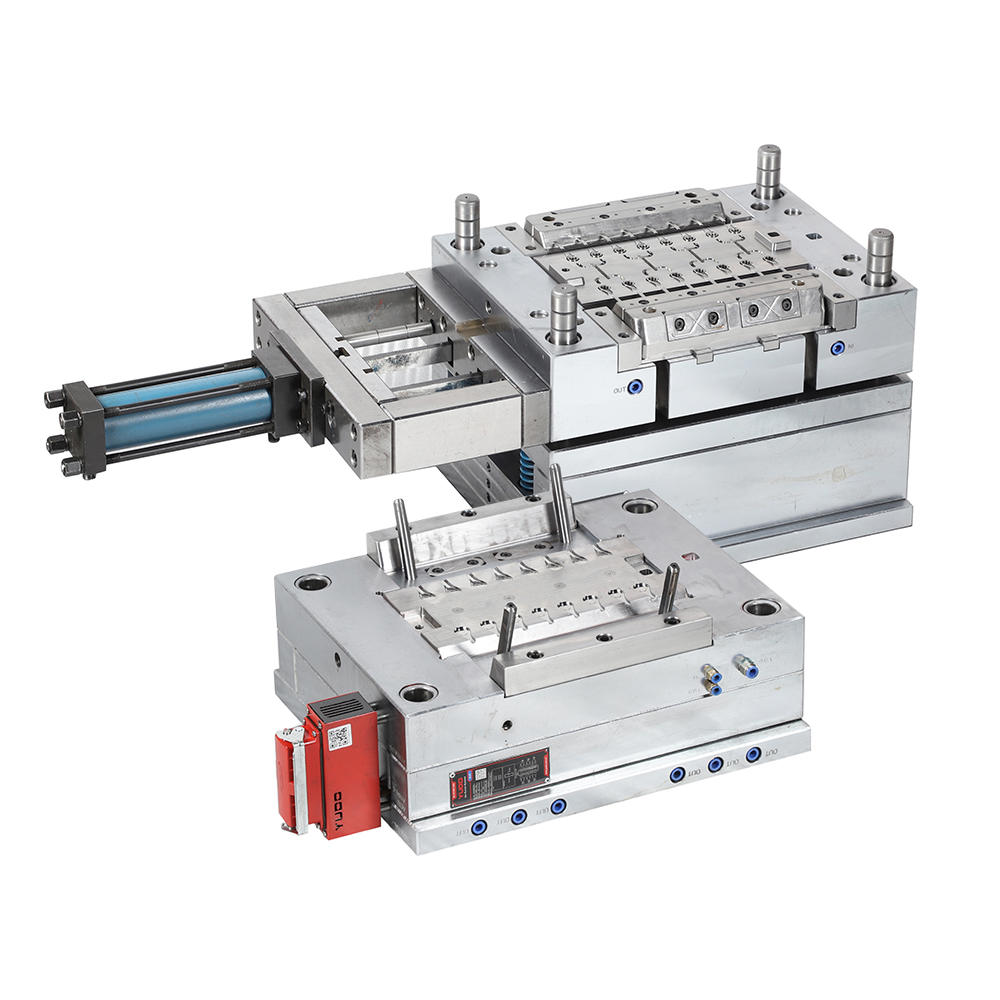

insertsGate inserts:High quality stainless steel with highly polished surfaces.Cores and cavities:High quality stainless steel with vacuum quenching heat treatment .Neck rings:High quality stainless steel with water cooled channel and air channel.Exchangeable insertUniform preform thickness distributionValve gate system add short tail hot runner system option for the jar preform moldWell-Balanced Layout of Flow Manifolds

- The special layout of flow manifolds and nozzle for PET

- Short cycle time

- Lower AA levels

- Lower energy consumption

- Reduced hold time and pressure

- Reduced maintenance cost.

Flow manifold : stainless steel 4cr13 , anti-corrosion in whole life ; Hot nozzle use PCT (USA); valve needle use punch industry japan ;heat insulation cap use Du pont (USA);heating coil use ROTFIL(Italy)or HOTSET(Germany).

High-Quality PET performNo crystallizationNo scratchHigh quality surfaceLow acetaldehyde (AA) levelminimum eccentricityconsistent weightflashless split-lines -

Frequently Asked Questions

Search for answers to your question

In good quality, and in good faith

We are famous Jar mould maker, manufacturers, and suppliers in China. Products are widely used in food packaging, daily packaging, chemical packaging, agricultural packaging, medical packaging and other industries. We help customer design Jar mould , manufacturing which fully reflects the continuous innovation tech. OEM/ODM production & service offered. Better Solution at Liangdian Mould.

-

6+ years

Industry experience

-

200+employees

Skilled technical worker

-

10000㎡

Factory floor space

Contact us

-

Address:

No. 16 huimin Road, Huangyan District, Taizhou City, Zhejiang Province, China

-

Phone:

+86-13606682107

+86-13575896814 - Email:

If you need it, please contact us!

Specializing in R&D, production and manufacturing of injection cap moulds, capping moulds, preform moulds, thin-wall moulds, daily necessities moulds, etc. Cover mold products are widely used in food packaging, daily packaging, chemical packaging, agricultural packaging, medical packaging, etc.

Latest News

- Follow us to know more -

-

How Sprayer Pump Mold Shapes the Future of the Cleaning Spray Industry

17-05-2024OEM Durable Shampoo Pump Sprayer Pump Mould Maker In China In the cleaning spray industry, we know how important a precise and durable Sprayer Pump Mo...

View More -

How Compression Cap Mould Shape the Cable Manufacturing Process

10-05-2024Cheap Modern Automatic Compression Cap Mould Price in China In the field of cable manufacturing, Compression Cap Mould plays a vital role. This mold i...

View More -

The Importance of Plastic Bottle Handle Molds in Modern Manufacturing

03-05-2024OEM China design of the plastic bottle handle mold Manufacturer In today's rapidly developing plastic products market, plastic bottle handle molds pla...

View More -

Our Concepts And Prospects

26-04-2024Over the past few decades, China's bottle cap mould industry has achieved significant development. With the advancement of science and technology and ...

View More -

Marketing Strategies That Cater to the Market

19-04-2024The medical industry is developing rapidly, and people's demand for medical devices is also growing. As an important part of medical equipment, medica...

View More -

Why We Can Stay Competitive?

12-04-2024With the increasing awareness of environmental protection, edible oil packaging has gradually become a new favorite in the market. In order to meet th...

View More

English

English 中文简体

中文简体 Español

Español