-

Products Parameter

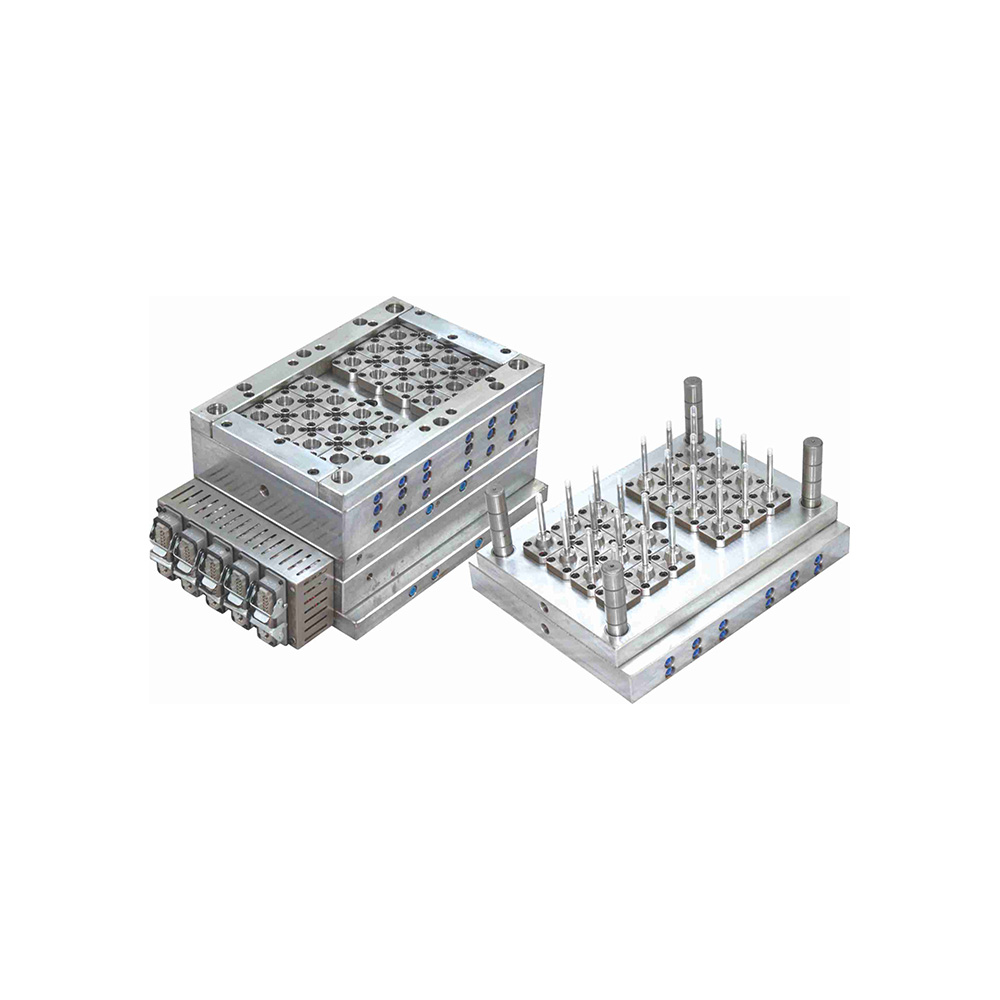

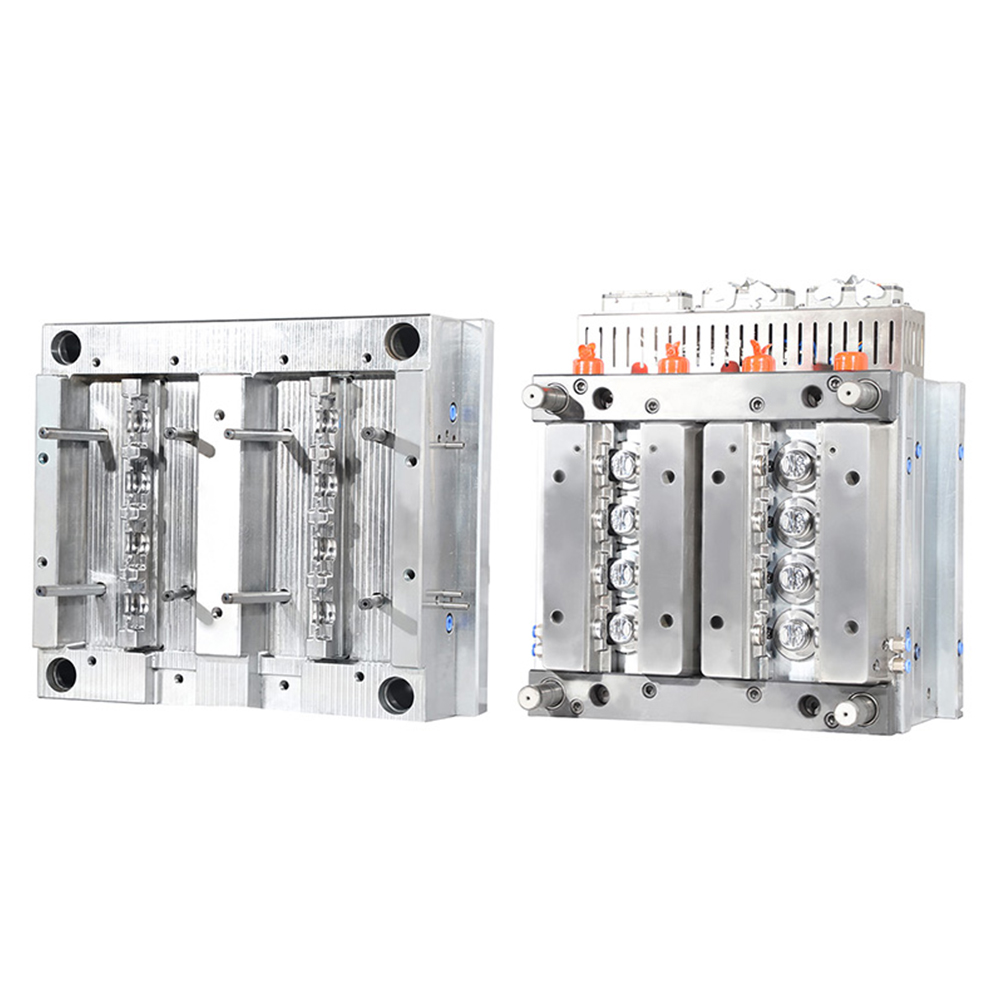

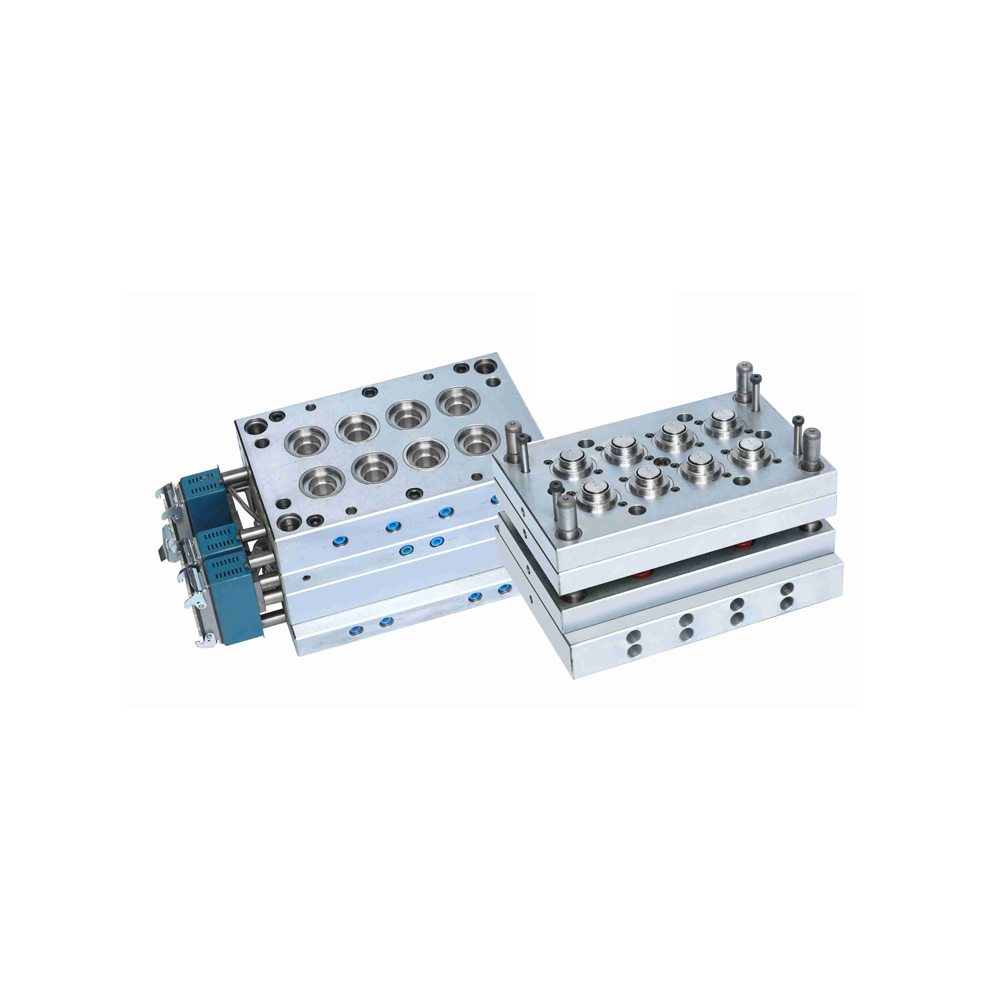

Mould name

Tube test mould

Mould cavity

8cavity ,16cavity,24cavity,32cavity,48cavity

Insert material

Cavity : S136, Hardness :47-50° ;

Core:H13 ,Hardness 47-50 °;

Core surface need nitriding or QPQ treatment ,It is according to the mould parts hardness request ,after treatment the surface hardness around 60-90 °

Mould plate material

P20 718 S136 according to client’s request

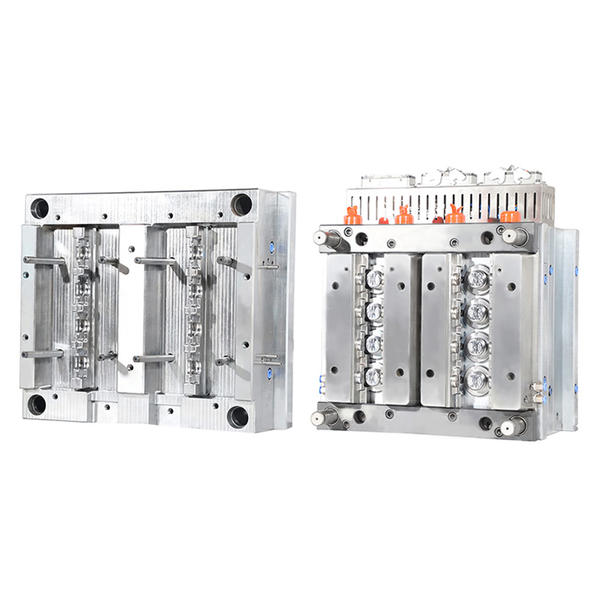

Runner type

Cold runner / hot runner , according to client’s request

Hot runner system

The temperature difference under controlling within1℃difference it makes sure that the raw material cann’t be burnt inside of hot runner. The wastage will be kept less than 1% .

Hot runner made by our own factory.You also can choose YUDO,SINO,HUSKY or other famous brand hot runner system as your choice.We have cooperation with all the hot runner system supplier.

Mould spare parts

8 cavity : 1 set spare parts ; 16 cavity :2 sets spare parts;…….

Surface finish

high gloss polishing

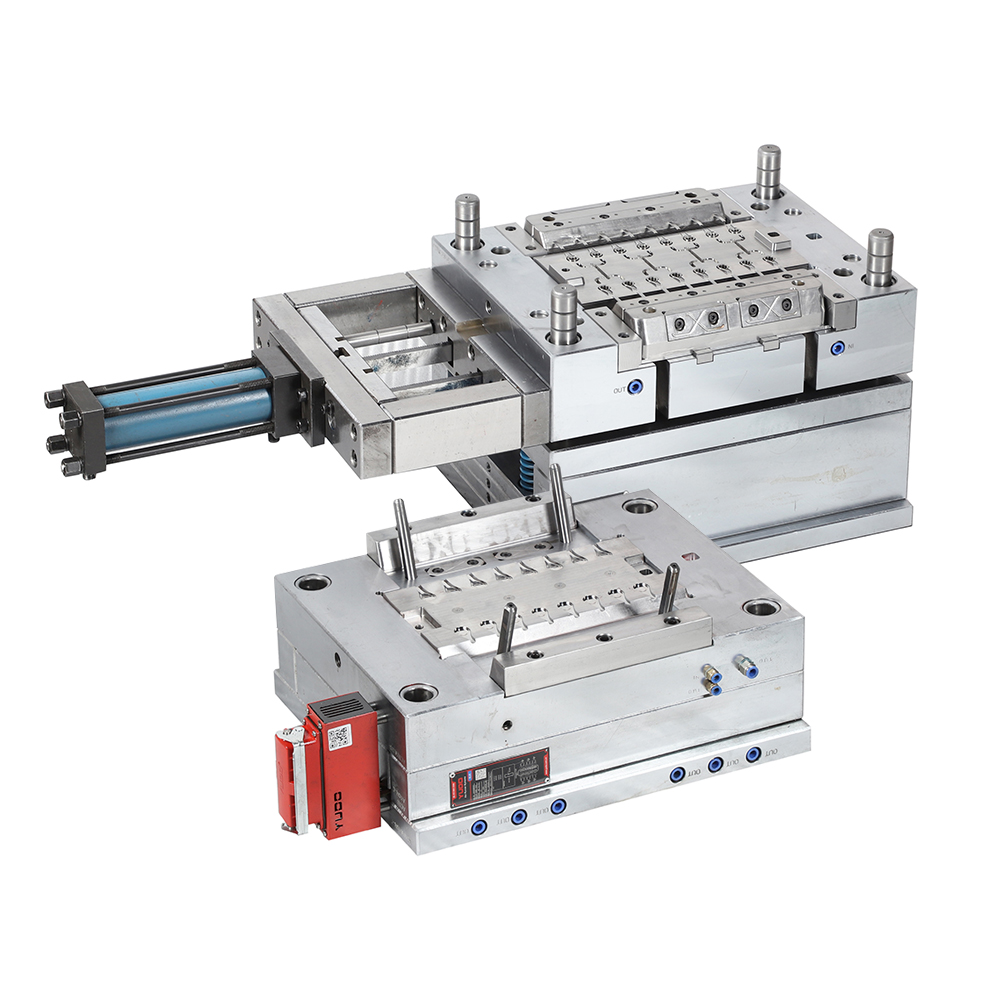

Ejection system

stripper plate

Warranty

1year or 1million shots

Mould package

Wooden box

Mould delivery time

45-60days

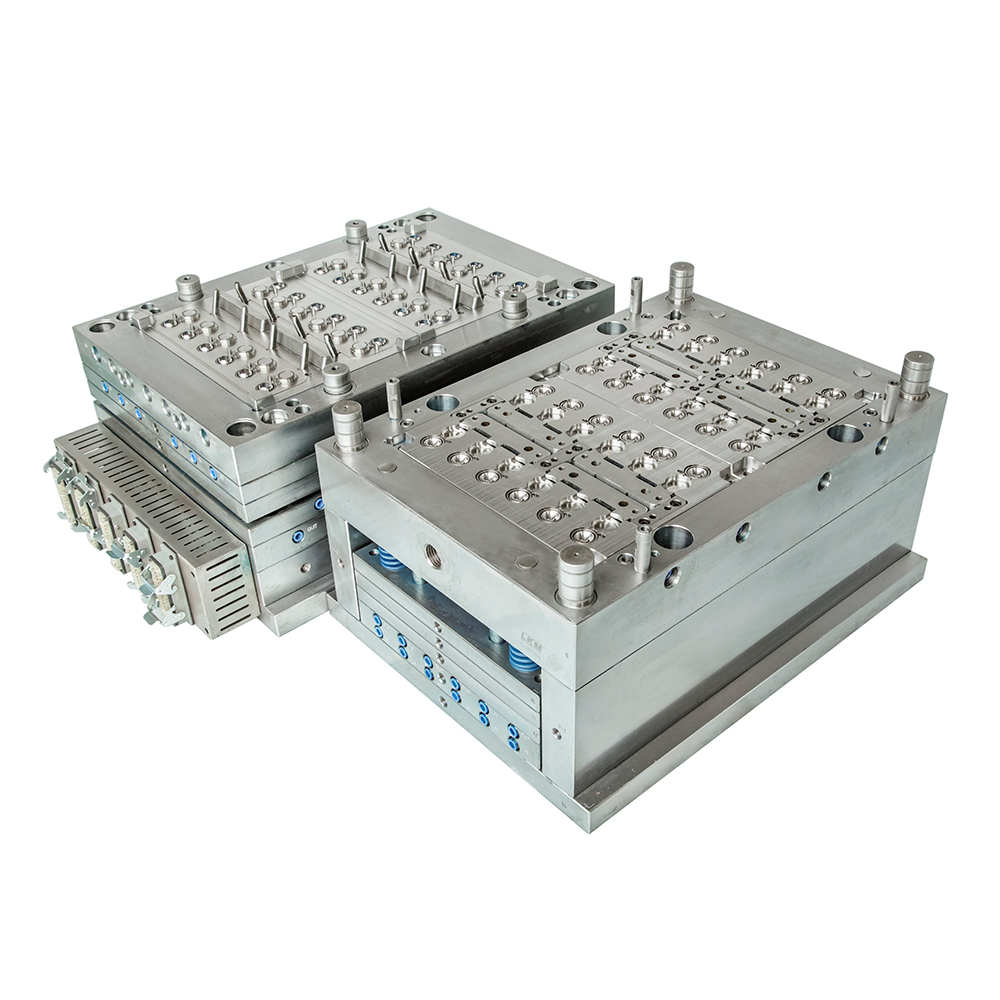

The mainly material and each material hardness

Material p20 718H 2738H H13 S136 NAK80

Hardness 33-37 33-38 36-40 47-50 47-50 34-40

Plastic mould features1、Mold ranges from 1cavity to 48cavities.2、Standard interchangeable components with fine polishing ,high hardness and anti-corrosion to make assure mold’s high precision and good quality.3、All of parts are manufactured by CNC equipments.4、High performance hot runner system ensures uniform melt flow and pressure in all cavities.5、Special designed water hoses eliminate leakage and well cooling system will improve production efficiency.6、mould base electroplating with chrome , effective against rust and corrosion within 3 years. -

Frequently Asked Questions

Search for answers to your question

In good quality, and in good faith

We are famous Test tube mould maker, manufacturers, and suppliers in China. Products are widely used in food packaging, daily packaging, chemical packaging, agricultural packaging, medical packaging and other industries. We help customer design Test tube mould , manufacturing which fully reflects the continuous innovation tech. OEM/ODM production & service offered. Better Solution at Liangdian Mould.

-

6+ years

Industry experience

-

200+employees

Skilled technical worker

-

10000㎡

Factory floor space

Contact us

-

Address:

No. 16 huimin Road, Huangyan District, Taizhou City, Zhejiang Province, China

-

Phone:

+86-13606682107

+86-13575896814 - Email:

If you need it, please contact us!

Specializing in R&D, production and manufacturing of injection cap moulds, capping moulds, preform moulds, thin-wall moulds, daily necessities moulds, etc. Cover mold products are widely used in food packaging, daily packaging, chemical packaging, agricultural packaging, medical packaging, etc.

Latest News

- Follow us to know more -

-

Comprehensive How-To Guide for Sports Cap Molds

30-08-2024Sale China sport cap mould Factory Supplier At Cap Mold Factory, we understand the importance of sport cap moulds. As a professional mold manufacturin...

View More -

Manufacturing Process and Good Quality

23-08-2024OEM water bottle cap mould Factory Maker In China At Cap Mold Factory, we know the importance of a water bottle cap mould. It is not just a simple acc...

View More -

The Role of Cap Mold in Various Fields

16-08-2024Cheap Cap Mould Factory Price in China In the vast world of manufacturing, Cap Mold Factory has become a success in the field of plastic cap molds wit...

View More -

Plastic Bottle Cap Mold Solutions from Cap Mold Factory

09-08-2024OEM China plastic cap mold Factory Manufacturer In today's rapidly developing era, plastic products have penetrated into every aspect of our lives. As...

View More -

The Design and Production Journey of Bottle Cap Mold

02-08-2024Custom water bottle cap mould Factory In the vast world of manufacturing, Bottle Cap Mold is our pride. It not only represents our exquisite pursuit o...

View More -

Future Market Outlook

26-07-2024Sale China sport Bottle cap mould Supplier In today's rapidly changing market, as a professional Bottle Cap Mold manufacturer, we are deeply proud to ...

View More

English

English 中文简体

中文简体 Español

Español